We provide Calibration And Measuring Equipments, Thread Gauges, API Thread Gauges, API Thread Profile Gauges, API Instrument, Plain Gauges, , Measuring Pins, Spline Gauges, Air Gauges, Calibration And Measuring Equipements, and our setup situated at Pune, Maharashtra, India

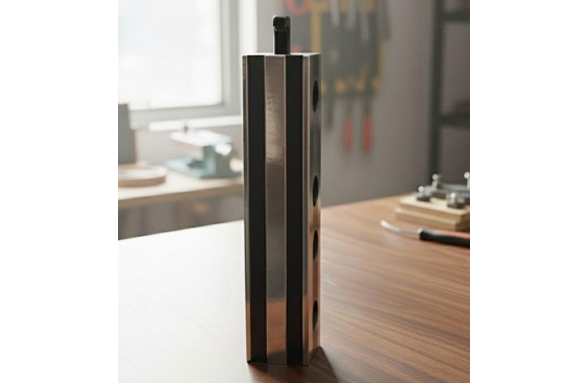

Slip gauges, also known as gauge blocks or Jo blocks, are precision tools used as a standard for linear measurement. They are manufactured to a specific thickness and have two opposing faces that are perfectly flat and parallel. They come in sets of different sizes, which can be combined to achieve a wide range of precise lengths.

Grades and Materials

Slip gauges are classified into grades based on their accuracy and intended use:

- Calibration Grade (K): The highest grade, used for calibrating other gauges and in metrology labs.

- Grade 00: Used for high-precision work in controlled environments, often for checking Grade 0 and Grade 1 gauges.

- Grade 0: An inspection grade used in tool rooms for high-accuracy work.

- Grade 1: Used for more precise work, such as setting up sine bars or checking gap gauges.

- Grade 2: A workshop grade for general-purpose work, such as setting up machine tools or rough checks.

They are typically made from hardened alloy tool steel, but can also be made from materials like tungsten carbide or ceramic for increased hardness, wear resistance, and dimensional stability.

Applications

Slip gauges are indispensable in metrology and precision machining for a variety of tasks:

- Calibration: They are the primary standard for calibrating other measuring Instrument like micrometers, calipers, and dial indicators.

- Reference: They are used as a reference standard for transferring the unit of length from a primary standard to other gauges.

- Setting up Machines: In machine shops, they are used to accurately set the height of cutters or to position workpieces.

- Inspection: They can be used with comparators to inspect a batch of components and quickly check if they meet dimensional requirements.

- Angular Measurement: When used with a sine bar, they can be used to set and measure angles with high precision.

| SLIP Gauge Metric Sets | SLIP Gauge Inch Sets |

| Set of 122 pieces (M122/1) | Set of 81 pieces ( E81) |

| Set of 112 pieces (M112/1 )(M112/2) | Set of 41 pieces ( E41 ) |

| Set of 88 pieces (M88/1) (M88/2) | Set of 36 pieces( E36 ) |

| Set of 47 pieces (M47/1) | Set of 9 pieces (E9 ) |

| Set of 46 pieces (M46/1) (M46/1) | Set of 2 pieces ( E2 ) |

| Set of 32 pieces (M32/1) (M32/2) | |

| Set of 18 pieces (M18/1) (M18/2) | |

| Set of 09 pieces (M9/1) (M9/2) | |

| Set of 02 pieces (M2/1) (M2/2) |

Length bars are highly precise, cylindrical standards used in metrology to verify or calibrate the accuracy of other measuring tools over long distances. They are a more robust and practical alternative to long sets of gauge blocks for large-scale measurements.

Features and Construction

- Material: Length bars are made from high-grade, dimensionally stable steel with a low coefficient of thermal expansion to minimize errors from temperature changes.

- Form: They have a round cross-section, typically 22mm or 30mm in diameter, for greater stability and ease of handling. The ends are precisely ground and polished, allowing them to be "wrung" together—a process where the perfectly flat, lapped faces adhere due to molecular attraction, creating a near-perfect seal with no air gap. This allows for the creation of a single, continuous standard of a specific length.

- Reference Grade: The most accurate, used to establish and maintain national standards.

- Calibration Grade: Used to calibrate other inspection-grade bars and high-precision measuring tools.

- Inspection Grade: Used in quality control to verify and set Instrument like micrometers and height gauges.

Applications

Length bars are essential in dimensional metrology for a variety of applications:

- Calibration of Large Instrument: They are used to calibrate or verify the accuracy of large measuring tools such as Coordinate Measuring Machines (CMMs), vernier calipers, and micrometers over extended ranges.

- Setting Up Machines: They are used to set up and check the travel of machine tools and jigs, ensuring accuracy during manufacturing.

- Traceability: Length bars provide traceability to national and international standards.

- Checking Large Workpieces: They are a practical way to check the dimensions of large workpieces that would be difficult to measure with other tools. They can be joined together using threaded connectors at the ends to create custom lengths far exceeding what a single length bar or gauge block could offer.

Angle gauge blocks, often called angle gauges, are precision tools used for measuring and setting angles with high accuracy. They are considered superior to other methods like sine bars because they don't rely on complex trigonometric calculations.

Angle gauge blocks are typically made from hardened, wear-resistant steel or chromium carbide. Their defining characteristic is the extreme precision of their two working faces, which are lapped and polished to be flat and parallel within a few millionths of an inch.

Features

- Construction: Angle gauge blocks have two highly precise measuring surfaces. Sets are designed so that the blocks can be "wrung" together. This process, which creates a strong adhesive bond due to molecular attraction and an ultra-thin film of oil, allows for the addition or subtraction of angles.

- Sets: Angle gauge blocks come in sets with specific angle combinations. A common set might include blocks in degrees (e.g., 1°, 3°, 9°, 27°, 41°), minutes (e.g., 1', 3', 9', 27'), and seconds (e.g., 3", 6", 18", 30"). By wringing these blocks together, a user can build almost any angle with very high precision.

- Wringing: Blocks are wrung together by sliding one over the other with a slight twisting motion. The clean, flat surfaces adhere to each other, creating a combined block with a new, highly accurate angle. The blocks are marked with a plus (+) and minus (-) sign to indicate which direction to orient them for adding or subtracting an angle.

Grades and Accuracy

Angle gauge blocks are available in various grades of accuracy, similar to their linear counterparts. The accuracy is typically expressed in "seconds of arc" (1 second = 1/3600 of a degree).

- Working Grade (Grade 2): These are the most common and are used for general shop or tool room applications. They typically have an accuracy of 5 seconds of arc.

- Calibration Grade (Grade 1): These are higher precision blocks used in inspection rooms to calibrate other Instrument. They have an accuracy of 2 seconds of arc.

- Reference Grade (Grade 0): These are the highest accuracy blocks, used as master standards in calibration laboratories. They can have an accuracy of 1 second of arc or even higher.

- Thread Measuring Accessories: For measuring threads, specialized accessories are essential. This includes.

- Thread measuring wires: Used in the three-wire method for highly accurate pitch diameter measurement of external threads.

- Thread measuring balls or styli: Used with dial indicators for internal thread measurements.

- Vee holders: These fixtures hold thread plug gauges or other threaded components for stable measurement.

- Gauge Holders and Fixtures: These accessories are used to secure and position a wide variety of gauges for calibration. Examples include

- Gauge clamps: Used to hold plain plug or ring gauges.

- Snap gauge holding attachments: Specifically designed to hold for calibration.

- Bore Gauge Calibration Unit: Used for Bore gauge calibration transmission accuracy

- Dial Gauge Calibration Unit: For calibration of Plunger type and Lever type dials.

A squareness master is a precision tool used to calibrate and verify the perpendicularity of a measuring instrument's axes. It's an essential part of quality control for machines like coordinate measuring machines (CMMs) and optical comparators, where the accuracy of measurements depends on the precise alignment of the machine's axes

A coating thickness gauge, also known as a DFT (Dry Film Thickness) meter, is a non-destructive testing instrument used to measure the thickness of a coating on a substrate without damaging the coating or the base material. This measurement is critical for quality control, ensuring that a coating meets the manufacturer's specifications for performance, durability, and cost.

Coating thickness gauges utilize different principles based on the type of substrate material.

Features

- Magnetic Induction: Used for non-magnetic coatings on ferrous (magnetic) substrates, like steel and iron. The gauge's probe contains a coil that generates a magnetic field. When the probe is placed on a coated surface, the magnetic field interacts with the ferrous substrate. The thickness of the non-magnetic coating (e.g., paint, zinc, chrome) affects the strength of this magnetic field. The gauge measures this change in magnetic flux and translates it into a thickness reading. A thicker coating results in a weaker magnetic attraction.

Applications

DFT meters are widely used across various industries where coating quality is essential. Some common applications include:

- Automotive: To verify the thickness of paint and powder coatings on car bodies to prevent corrosion and ensure a uniform, high-quality finish.

- Manufacturing: For quality control of protective or decorative coatings on a wide range of products, from household appliances to industrial equipment.

- Construction: To inspect protective coatings on structural steel, pipelines, and bridges to ensure they meet corrosion protection standards.

- Aerospace: For measuring coatings on aircraft components to ensure proper protection and performance.

Thickness foils and shims are thin, flat pieces of material used in engineering and manufacturing to fill small gaps, adjust alignment, or act as a spacer. The terms are often used interchangeably, but "foil" usually refers to very thin, flexible material, while "shim" can also be a thicker, more rigid piece.

Types

Thickness foils and shims come in a variety of materials and forms, each suited for a specific application.

- Materials: They are commonly made from metals like stainless steel, brass, copper, and aluminum, chosen for their durability, corrosion resistance, and specific properties. Plastic or other non-metallic materials are also used for less demanding applications.

- Laminated Shims: Made of multiple thin layers bonded together. You can "peel" off layers to achieve the exact thickness needed, which is ideal for fine adjustments in the field.

- Pre-cut Shims: These are shims that have been pre-cut to specific shapes and sizes to fit common applications, like aligning machinery feet or gears. They save time and reduce waste.