KVR International is a dynamic and customer-focused supplier and manufacturer of high-precision gauges based in Pune, Maharashtra, India. We specialize in a comprehensive range of quality-tested and durable products, including Thread Gauges and API Gauges, designed to meet the rigorous demands of various industrial applications.

Since our inception, our mission has been to provide superior gauging solutions that guarantee dimensional accuracy and exceptional performance. We are dedicated to ensuring that every product we supply, from Thread Plug Gauges to API Thread Gauges, is meticulously crafted for reliability and wear resistance.

At KVR International, we pride ourselves on being a trusted partner for industries worldwide. Our commitment to excellence, coupled with our in-depth knowledge of metrology, allows us to deliver products that are not just tools, but a testament to our quality-driven ethos. As we continue to grow, our focus remains on innovation, precision, and building lasting relationships with our valued clients.

We are committed to excellence. We partner with industries to supply products that ensure dimensional accuracy and reliable performance, helping our clients maintain stringent quality control. Our foundation is built on precision, quality, and a deep understanding of our customers' requirements, making us a dependable name in the market.

KVR International: Your Partner in Precision Measurement in Pune, Maharashtra

With decades of experience in the field of metrology, KVR International has established itself as a leading name in the manufacturing and calibration of high-quality precision gauges and measuring Instrument. Located in Pune, Maharashtra, we are committed to providing exceptional products and services that meet the stringent demands of various industries.

Our journey began with a simple yet powerful mission: to deliver accuracy and reliability in every product we create. Today, we are proud to be a trusted partner for businesses across India, offering a comprehensive range of products and services, including:

- Thread Gauges: Manufacturing a wide variety of thread gauges for precise measurement of internal and external threads.

- API Gauges: Specializing in the production of API gauges for the oil and gas industry, ensuring compliance with global standards.

- Measuring Pins & Slip Gauges: Producing high-precision measuring pins and slip gauges, essential for calibration and dimensional inspection.

- Spline Gauges: Manufacturing specialized spline gauges for checking splined components.

- Customized Gauges: Providing bespoke gauging solutions tailored to your unique application and specifications.

- Other Precision Products: Our extensive product line also includes thread measuring wires, air gauges, thread rolls, setting gauges, , and multi-gaging systems.

In addition to our manufacturing expertise, we offer NABL accredited calibration services for a wide range of measuring equipment. Our state-of-the-art laboratory and experienced technicians ensure that your Instrument are calibrated to the highest standards, providing you with the confidence and traceability you need for your quality control processes.

At KVR International, we believe in building lasting relationships with our clients through superior quality, timely delivery, and unparalleled customer service. We are more than just a manufacturer; we are your dedicated partner in precision.

Standard Procedure of Gauge Manufacturing (General Information)

The manufacturing process for precision thread gauges typically follows a rigorous, multi-step procedure to ensure accuracy and durability. Here is a general outline of the steps involved:

- Material Selection: High-quality, wear-resistant tool steel is selected. The type of steel (e.g., high carbon steel, carbide) depends on the gauge's intended use and the required hardness.

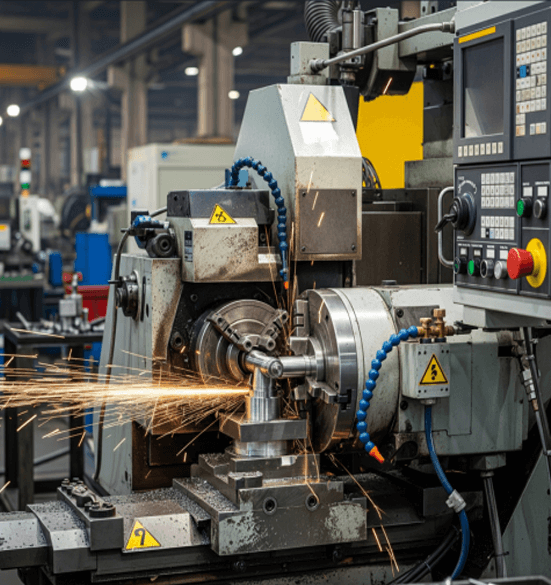

- Rough Machining: The raw steel is cut to size and roughly turned on a lathe to create the basic shape of the gauge.

- Heat Treatment: The gauge blanks undergo a carefully controlled heat treatment process, including hardening and tempering. This process is crucial for achieving the required hardness and stability, which prevents the gauge from deforming during use.

- Precision Grinding: After heat treatment, the gauge's external and internal diameters are precision ground to a very tight tolerance. This step removes the scale from the heat treatment and prepares the surface for thread grinding.

- Thread Grinding: This is one of the most critical steps. A specialized thread grinding machine uses a precision-ground wheel to create the thread form. The machine is meticulously calibrated to ensure the thread's pitch, angle, and diameter are correct according to the specified standard (e.g., ISO, ANSI).

- Lapping and Finishing: The thread surfaces are lapped to achieve a smooth, low-friction finish. This process can be done manually or with specialized lapping machines. It improves the feel and extends the life of the gauge.

- Final Inspection and Calibration: Every finished gauge undergoes a comprehensive final inspection in a climate-controlled inspection room.

Instrument used: High-precision Instrument like thread micrometers, optical comparators, and three-wire systems are used to verify the pitch diameter, major diameter, and minor diameter.

Certification: A certificate of calibration is typically provided with each gauge, confirming that it meets all specified standards.